Description

SiMR-1912C is a reaction product of silicone resin with silicone fluids, which forms durable water-repellent release films. Thesefilms have much better affinity than is attainable with polydimethylsiloxanes and many organomodified silicone fluids ofcomparable viscosity. SiMR-1912C serves as a component in polish and release agent formulations.

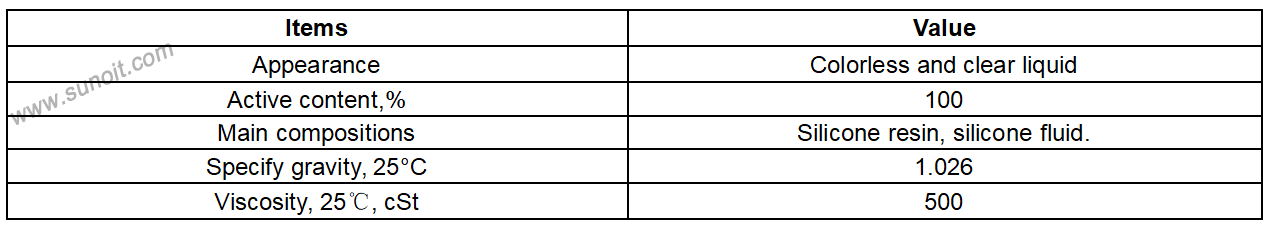

Product Data

Application

• Car Care

• Car Polishes

• Plastic-Care Products

• Polyurethane Processing

How to use

When used as a release agent:

Dry and clean the surface before use.The recommended dilution range is 10-40 times. Brush or spray the diluted products on mold surface. Dry the surface until a thin and dry film on mold surface forms.

Notes:

• Solvents used to dilute SiMR-1912C may beflammable, so be careful when applying diluted solutions to hot surfaces.

• The frequency depends on complexity of the mold and the molding material (usually every 1 to 6 re-sprays of release agent). A trial test is recommended for optimum dosage.

• Uneven dispersion may also cause difficulty in demolding.

• Heat curing helps improve the release and durability of the release film. Recommended curing temperature/timeis around 100°C for 5–10 minutes.

• In some cases, the silicone release film formed by SiMR-1912C can interfere with the painting and bonding of molded parts. A full test is necessary before use.

As an ingredient in car polish formulation:

SiMR-1912C impartsdurable high gloss, water resistance, detergent resistance car polishes. Adding a small amount of amino silicone like SNY-290 to SiMR-1912C or compoundingwith organic waxes can improve its durability. SiMR-1912C is used in automotive polishes at levels of 1–5% by weight. A trial test before use is recommended for optimum dosage.

Contact: Kobe.Mao

Phone: +86 18758212253

Tel: +86 18758212253

Email: info@sunoit.com

Add: 159th Longzhang Road, Hangzhou, Zhejiang Province, China

We chat